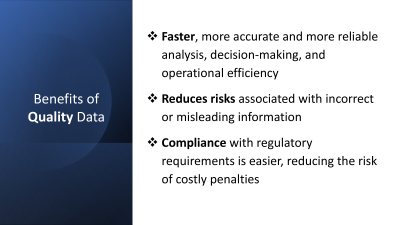

International Standards for formatting master data can lower purchasing and inventory costs and at the same time reduce supply chain risk. Through enhanced data quality in procurement and supply chain management, organizations could expect to reduce Inventory by 50%; reduce MRO costs by 15%; reduce Requisition error by 60%.

The duplication challenge within Master Data

Duplication of supplier and material master data records is one of the most common and avoidable causes of higher MRO costs and unnecessary supply chain risk. The application of international standards for formatting master data makes it easier to identify duplicate master data records within a business unit and across business units.

Supplier/Vendor Master Data

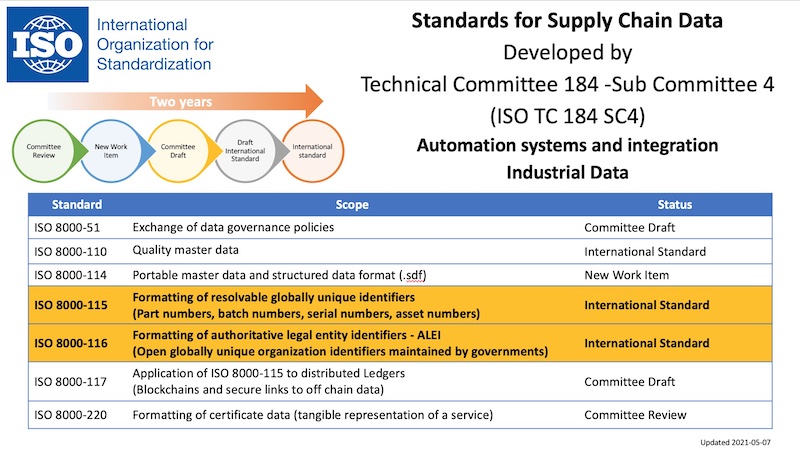

Improving a supplier or customer master is surprisingly simple and low cost, typically $1 per record. The process consists in verifying legal name, date of formation and status with the official government registry. ISO 8000-116 is the international standard for formatting the International Business Registration Number (IBRN), the reference created by the government registry when a legal entity is formed.

Beyond this the ISO 8000-116 formatted IBRN is an excellent open, universal and globally unique, supplier or customer identifier. In the same way you add a country code to turn a local telephone number into an international telephone number, ISO 8000-116 turns the local business registration number into an international identifier that is unique for each supplier by adding a prefix to the local business registration number to create an international business registration number (IBRN).

A typical supplier master will contain as many as 20% unidentifiable suppliers. This occurs where the name in the master data record can not be found in an official government registry. This can be a big problem for:

- procurement spend analysis

- supplier on-boarding programs

- due diligence/corporate fraud risk management

but luckily it is easily fixed – just by asking the supplier for an ECCMA IBRN Verification Certificate. Suppliers can obtain a free IBRN Verification Certificate from ECCMA by visiting the Know Your Supplier site and they can also use the site to make available public information their customers need such as office locations.

Once the legal name has been verified, it is common to find that there is a 30% duplication in the supplier master. This often means that items are being bought from the same supplier under different names and typically at different prices – a Category or Procurement Manager’s worst nightmare!

Material Master Data

A typical item/material master will also contain many duplicate records. 25% to 30% duplication in an item/material master is common. Improving the quality of an item/material master allows the identification of duplicate and substitutable items/materials which drives down purchasing and inventory costs while at the same time highlighting opportunities to optimize suppliers to reduce cost or reduce risk by identifying alternate suppliers. Improved item/material and service specifications and descriptions using international formatting standards for quality data makes managing bids and contacts easier as well as improves the accuracy of spend analysis.

Managing Master Data as a business-critical asset

Master data is a critical business asset that needs to be managed and protected. ISO 8000 protects master data from potential third part claims that can restrict its use. It is all too easy for data to be captured by the application used to collect and manage it. This is called Data Lock-in. Application providers can make it difficult (costly) to move data from their application to another. Requiring that an application supports ISO 8000 formatting is valuable insurance against lock-in. Just by asking (in writing) if an application can export ISO 8000 portable data is often sufficient to highlight and resolve any issues with data lock-in.

Another effective way to maintain quality master data is to ensure you ask vendors/suppliers to provide full data on the products/services you are buying. By mandating within your procurement contracts or standard Terms & Conditions of business that a supplier must provide you with International standards-based data on the items you are purchasing, you ensure you receive quality data from Day 1 of your trading relationship. A Supply Chain Data Formatting Clause can be included within contracts or standard Terms & Conditions.